Call us on 0114 275 4150 or or email us here

Branded Safety Wear

Browse below our online collection of branded safety wear.

Key Information

Why Choose Us

At Steel City, we select hi-vis and workwear with the same care we’d take if we were issuing it to our own crew. It’s really important that we check the standard first, and then choose garments that can take your branding beautifully without compromising on visibility.

We know that when you’re kitting out a site team, small misses can cause big delays. That’s why our proofing and repeat-order processes are so tight—we want to help you avoid those usual frustrations like the wrong class, the wrong shade of orange, or branding that sits across the tape. It’s about making sure that when you need a top-up, it matches your previous order perfectly.

- Standards that get you through the gate: So, our starting point is always EN ISO 20471 / EN471 Class 2 with UKCA & CE marking. We’ll also include GO/RT 3279 Issue 8 when you need that specific orange, because we know site gates often check class and colour before they check names. That choice really helps reduce the risk of your team turning up in the wrong spec and having to re-issue kit at the entrance.

- Branding that respects the reflective: It’s really important that our proofing flow checks the print or embroidery position before production. We know that reflective bands and hi-vis panels lose their impact if they get covered with stitching or ink. This keeps your logo placement off the tape and leaves the garment doing its main job when your team is working in traffic, plant areas, or low light.

- Consultative, task-based shortlists: Our team will suggest a tight set of options based on what you’re actually issuing for—whether that’s compliance hi-vis, clear ID pieces with usable print areas, or day-to-day workwear. We know that ordering blind can lead to the wrong garment type in the wrong sizes, so this allows you to place an order that fits the job perfectly without having to write your own spec sheet.

- Consistency on repeat orders: We aim to lock in sizing runs (often S-5XL / XS-5XL) and keep the same branding method per item. Swapping methods can change how big the logo looks and where it sits, and we want to keep your replenishment batches visually consistent so your crews don’t end up looking mismatched across sites.

- Fabric weight that lasts: We will always steer you towards hard-wearing polycotton workwear (typically 65/35) around 240-270gsm with reinforcement like bar tacks and twin-needle stitching. Lighter cloth and weak seams tend to fail first at knees, pockets, and stress points, and this reduces those early blow-outs when you’re kneeling, climbing, or carrying tools all day.

- Lead times you can plan around: We know lead time is a popular question, so our quotes show lead time by product line – commonly 10 working days from artwork approval. We’ll always flag faster options where they exist, because we know rushed swaps can arrive in the wrong spec or with branding that doesn’t match. This helps you hit start dates without gambling on last-minute substitutions.

- A brilliant baseline that’s upgradeable: Our team uses the items listed above as a really strong baseline because they give you workable compliance, sensible branding areas, and repeatable re-orders without extra back-and-forth. If you’re issuing at scale or have a special requirement, we can source bespoke alternatives and still run them through the same tight proofing and repeat-order controls.

Our Safety Wear Range

- Gate-check colour & class: We would recommend the Hi Vis Safety Waistcoat because we prioritise Class 2 hi-vis with UKCA/CE and GO/RT 3279 Issue 8 (orange option) where gates commonly ask for it. This gives you a simple issue item when you need fast compliance without having to debate specs at the site entry.

- Branding above the torso: We chose the 6 Panel Hi Vis Cap because the pre-curved peak and reflective tape keep head-level visibility up at dusk without using your vest or jacket as the only hi-vis surface. That lets you add readable branding on headwear while keeping your main hi-vis panels clear.

- Rechargeable task light: I think our pick of the Rechargeable LED Beanie really comes down to the rechargeable LED unit and 3 brightness levels. We know disposable lights die mid-shift and then the beanie turns into “just a hat.” This setup lets you start early or finish late with a light you can top up and use again.

- Fast extra reflectivity: We include the Hitz Reflective Slapwrap Wristband because the EN17353 compliant reflective material – plus a 3-day express option – really helps when visitors or extra crew turn up after you’ve placed your main PPE order. This gives you a quick add-on so you can issue something useful and visible without reopening the whole garment order.

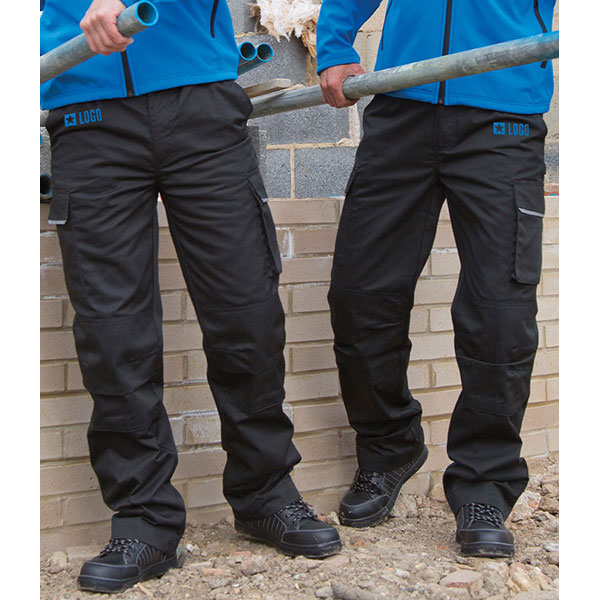

- Reinforced work trousers: We recommend the Result Workguard Action Trousers in 270gsm 65/35 polycotton with bar-tacked stress points. Pockets and seams are where cheap trousers split first, and we want to make sure the build holds up better when you’re kneeling, climbing ladders, and carrying tools daily.

- Ensuring issued kit stays together: We chose the Celsius Hi Vis Drawstring Bag – Full Colour because the 210D hi-vis fabric with a reflective strap makes the bag visible in a pile of gear. Plus, the 150 x 150mm full-colour print area gives you clear ID at handover, making it much easier for you to keep the right PPE grouped from stores to site.