Call us on 0114 275 4150 or or email us here

Logo Branded Workwear

Custom branded work clothing with your company logo.

Key Information

Why Choose Us

We know that when you’re kitting out site teams, engineers, or front-of-house staff, consistency is just as important as comfort. You want your team to look the part, and you need kit that lasts. At Steel City, we select workwear that avoids the usual headaches: peeling logos, split seams, and slipping delivery dates. Our job is to make sure your team feels proud to wear your brand, reducing the need for constant replacements.

- Consistent Reordering: We run orders through a dedicated account management process so garment choice, branding methods (whether embroidery or transfer print), and timelines stay stable once you’ve approved the artwork. This minimises errors in sizes or colours and stops those knock-on delays that come from last-minute changes.

- Precision Branding: We use defined branding areas because we want repeat orders to look exactly the same across your whole team. It prevents off-centre logos and ensures your branding never interferes with essential features like hi-vis reflective tape. You want your logo to be perceived as really good quality, and placement is key to that.

- Site-Ready Compliance: We curate compliance-ready hi-vis with clear standards (like EN471 Class 2 and UKCA/CE). It’s really important that when your team arrives at an induction, their kit matches what the site expects, so nobody gets sent away to change.

- Durable Branding: We choose branding methods like high-stitch embroidery and fabric-matched transfers so logos and names stay readable wash after wash. We want to avoid cracking prints or fraying threads that make a team look scruffy. If you wouldn’t wear it yourself, we wouldn’t suggest it.

- Quality Fabrics: Because thin uniform pieces can lose shape and go see-through, we steer our range towards polycotton twills, softshell layers, and sensible weights. It keeps the garments feeling like proper workwear when your team is moving all day.

- Reinforced Stitching: We prioritise bar tacking and twin-needle stitching because we know pockets and seams tend to fail first in busy roles. This reduces split seams and helps avoid the cost of early replacements.

- Clear Lead Times: We’re honest about lead times from proof approval – usually 5-10 working days – so you can plan around start dates and inductions. If you’re tight on time, we’ll let you know which kit can be branded and delivered within your window.

These products are our recommended benchmarks for fit, compliance, and reliability. However, if your rollout is bigger or you have specific needs, we can take a consultative approach to source alternatives that match your job roles and budget perfectly.

Our Workwear Range

- Induction-Ready Hi-Vis: We recommend the Hi Vis Safety Waistcoat because it makes the certification check straightforward when you arrive on site. With EN471 Class 2 and UKCA/CE certification (plus GO/RT 3279 Issue 8 on orange), it keeps you aligned with strict site inductions.

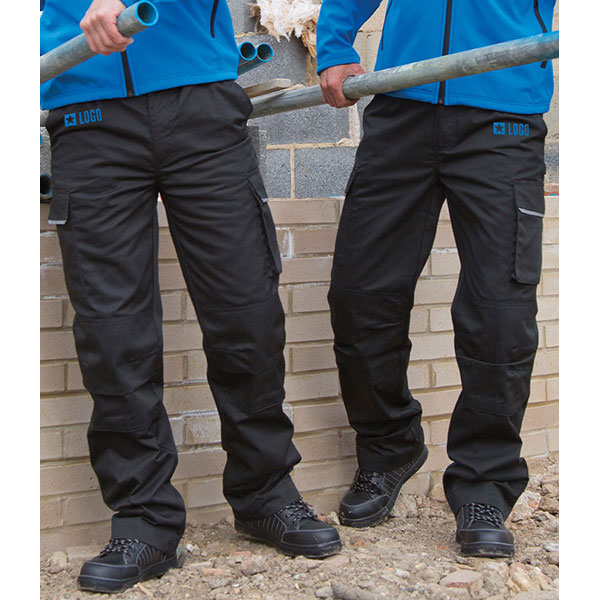

- Trousers That Last: We use the Result Workguard Action Trousers as a benchmark because we’ve seen lighter “promo” trousers fail. With bar tacking, twin-needle seams on 270gsm polycotton, and knee pad pockets, they stand up to the daily rigours of being in and out of vans or working on floors.

- A Smart Bodywarmer: We chose the Result Core Printable Softshell Bodywarmer because the two-layer softshell keeps its shape through daily wear. It helps you keep a cleaner, professional look at doorways and service calls, rather than a gilet that looks tired quickly.

- Professional Shirts: Because customer-facing teams need to look smart all day, we include the Kustom Kit Premium Long Sleeve Classic Fit Oxford Shirt. It’s an easy-iron, classic fit that keeps your uniform looking sharp across long shifts with minimal fuss.

- Apron With Storage: We picked the Bib Apron with Pocket so your staff have a proper place for order pads and pens during service. The large front pocket and adjustable neck keep essentials close and the uniform consistent when it’s busy.

- Fast Print Aprons: We chose the Pheebs Recycled Cotton Apron because it offers a clear, defined print area for your logo. Plus, if you’re working to an event deadline, the quick lead time from artwork approval helps you plan without the stress.