Call us on 0114 275 4150 or or email us here

Logo Printed Canvas Bags

Canvas Bags with your logo to impress your clients the ethical way, whether it’s at a conference, exhibition, tradeshow, or simply to carry around everyday items.

Our range of top quality canvas bags includes customised, Organic Cotton Shoppers, Aware Traceable cotton bags, Dyed Cotton Canvas Bags, Jute Bags, plus so much more.

Key Information

Why Choose Us

We know that when you put your logo on a product, you want it to be perceived as really good quality. At Steel City, we select canvas bags based on how they perform in the real world—whether that’s at an event or on the daily commute. We want to take the stress out of the decision for you, avoiding common issues like thin fabrics or awkward handles, so you can be sure your brand looks professional and the bag becomes a genuine essential for the recipient.

- Canvas weight strength: We always put forward fabric weights from 5oz up to 12oz. Thinner canvas can crease quickly and might get left behind, whereas heavier weights keep their shape better when used day-to-day. We want that bag to stay in the recipient’s rotation for the weekly shop or commute, keeping your brand visible.

- Base that stays square: We will often suggest gusseted builds (including 100mm and 150mm) because flat totes can buckle when loaded with catalogues or boxes. The added depth keeps the base flatter, meaning it’s far more useful for the person carrying it.

- Shoulder-friendly handles: We shortlist long handles (up to 63cm) and webbing options because comfort is key. If a bag is comfortable to carry between venues or to the station, it stays in use, and your brand continues to be seen.

- Print area that fits: We take a consultative approach to your artwork. We might suggest 1-colour printing for bold, cost-effective logos, or full-colour if you have gradients. We stick to generous print areas (e.g., 320×280mm down to 220×220mm) so your branding isn’t squeezed and looks exactly as it should.

- Proof-checked placement: It’s really important that our processes are tight. We check layout and positioning upfront and always provide a proof so you can sign off exactly what’s going on the bag before production starts.

- Documented recycled content: Sustainability is a real priority, but we want to make sure we don’t greenwash. We include options with AWARE™ digital product passport traceability, Global Recycled Standard (GRS) certification, and recycled cotton blends. This gives you the facts to back up your eco credentials if anyone asks.

- Lead times you can plan to: We know deadlines can be tight. We offer various lead times (from 5 to 15 days from artwork approval) to suit your schedule. We’ll always have that conversation with you to ensure you get the best quality bag available within the time you have.

- Repeat-run consistency: We use trusted, BPMA-accredited suppliers to minimize the risk of any surprises on reorders. It’s about ensuring the fabric feel and print placement remain consistent, so your brand is represented perfectly every time.

These suggestions are a great starting point, but we can always go further to find a bespoke solution if you have specific requirements for sizes, fabrics, or handles.

Our Canvas Range

- Heavy-load gusset: We picked the 12oz Exhibition Canvas Bag because the 12oz recycled canvas with a 150mm gusset stops the base collapsing when you’ve loaded it with brochures and boxed giveaways. Plus, the 63cm long handles mean you can shoulder-carry it all day comfortably.

- Big logo at distance: Our reason for suggesting the Natural 10oz Canvas Cotton Shopper – 1 Colour is simple: the 10oz fabric and full gusset (420×380×100mm) prevents that thin-tote sag, and the 320×280mm print area keeps your logo readable without shrinking it. It’s a great way to keep costs under control while staying bold.

- Full-colour detail control: We use the Black 10oz Canvas Cotton Shopper – Full Colour as a go-to when your artwork can’t be reduced to a single ink without losing detail. The 10oz canvas holds its shape, and the full-colour print ensures your design really lands well, even with gradients.

- Webbing handle support: We specified the Green & Innocent Kongoni 10oz Canvas Bag – 1 Colour with a 150mm dyed jute gusset and long cotton webbing handles because that setup offers real structure. It resists the sag-and-curl of thinner bags, making it a product people will want to use long after the event.

- Traceable fibre paperwork: We include the AWARE Recycled 5oz Natural Cotton Shopper – 1 Colour because the AWARE™ recycled cotton + rPET with a digital product passport gives you full traceability. It’s important to have that transparency if you are making public sustainability claims.

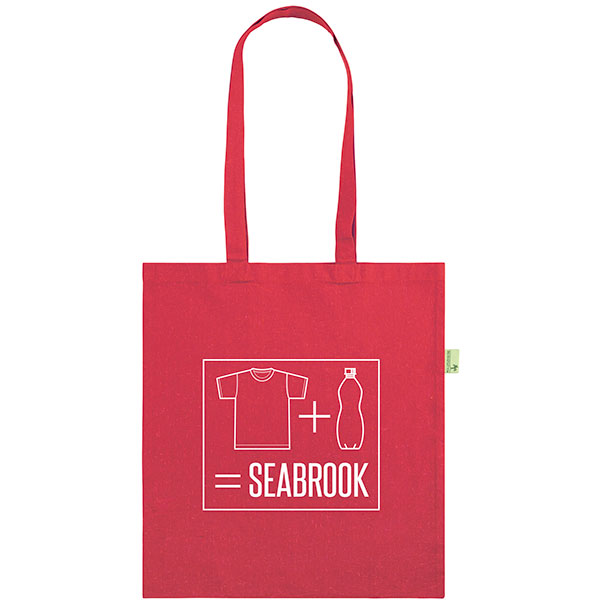

- Stated recycled blend: We chose the Seabrook 5oz Recycled Cotton Tote Bag – 1 Colour because it states the blend clearly (60% recycled cotton / 40% rPET) and comes with a reliable 7-day lead time. It removes the vague “eco” wording and gives you a concrete spec you can trust.