Call us on 0114 275 4150 or or email us here

Printed Shopping Bags

Promotional shopping bags printed with your custom logo and branded message, available in a range of materials and styles, as well as express delivery for short deadlines. Branded bags are perfect for getting your branding in front of potential customers at scale.

Steel City Marketing offer a personal service, with a dedicated account manager, and free visuals so everything is agreed upon before you order. We’re a 40-year member of the BPMA, with a long-standing history of helping companies with branded merchandise.

Contact us today for a quote, or browse our products below.

Key Information

Why Choose Us

At Steel City, we approach shopper bags by looking at exactly what you’re going to be putting in them and how they’ll get carried. The aim is simple: we want to stop handles ripping, seams bursting, and prints looking tired halfway through the day.

- Fabric that matches the load: We offer options ranging from 80gsm GRS rPET non-woven to 5oz-12oz cotton/canvas and laminated jute/juco. We do this so you don’t end up forcing a light fabric to do a heavy job, watching the bag sag or split. If you’re handing out brochures, boxes, or welcome packs, the heavier weights and structured options take the strain instead of the stitching.

- Print that stays consistent: We start with your artwork and then choose the best method – whether that’s 1-colour spot, full-colour digital, or Pantone matching. This ensures your logo placement and colour stay consistent across the order rather than drifting between batches. If a material or base colour might shift the result, we’ll always flag it on the proof before anything goes to print.

- Lead times you can plan around: We keep short-turn options (often 5-10 working days) in the mix alongside longer runs for specialist recycled builds. We know the worst time to change spec is a week before an event. If your date is fixed, this lets us keep the bag weight sensible instead of dropping to a thinner tote just to hit a deadline.

- Gussets that stop bowing: We stick to usable formats like 420 x 380mm, often adding deeper gussets (up to 150-200mm) because flat bags can bow at the sides when loaded. That base depth holds the weight in the bottom panel, so you’re not dragging the side seams and handle joins every time you lift it.

- Handles that don’t give up: We lean toward longer carry handles and stronger fabric weights (including 10oz-12oz canvas and 600D polyester) because short handles and light cloth can rip when you’re carrying a full show bag for hours. If your team is walking a venue all day, these specs stop that “handle tear, contents on the floor” moment.

- Eco claims you can evidence: We put forward GRS-certified recycled materials, traceability options, and rPET made from recycled bottles. This gives you something real to point to when someone asks “what makes this eco?”. If your sustainability brief includes where it’s made and how it’s traced, we use those standards to avoid vague “green” labels.

- Finish that holds shape: Our range includes zips, internal pockets, wipe-clean laminated surfaces, and rope-handle carriers because thin bags crease fast and can look scruffy after the first handout. If your bag needs to look like part of a retail experience, these upgrades keep it structured in photos and presentable on the journey home.

The products shown above are our starting point benchmarks for this category. We use them as standards for capacity, print control, and lead times, and we can often source bespoke alternatives when your quantities and schedule allow.

Our Shopper Range

- 12oz gusset stability: We suggest the 12oz Exhibition Canvas Bag because it stays open and carries weight without the sides collapsing; the 550 x 360 x 150mm gusseted 12oz recycled canvas takes brochures and samples without bowing the seams. That 63cm handle length lets you get it on your shoulder comfortably when your hands are full at an event.

- Readable print area: Our pick for budget volume is the Non-Woven Cotton Shopper – 1 Colour because we didn’t want you stuck with tiny artwork on a throwaway tote. The 320 x 280mm print area keeps your logo and message clear at arm’s length, while the 80gsm GRS rPET non-woven keeps the unit cost down without dropping into a “single-use” feel.

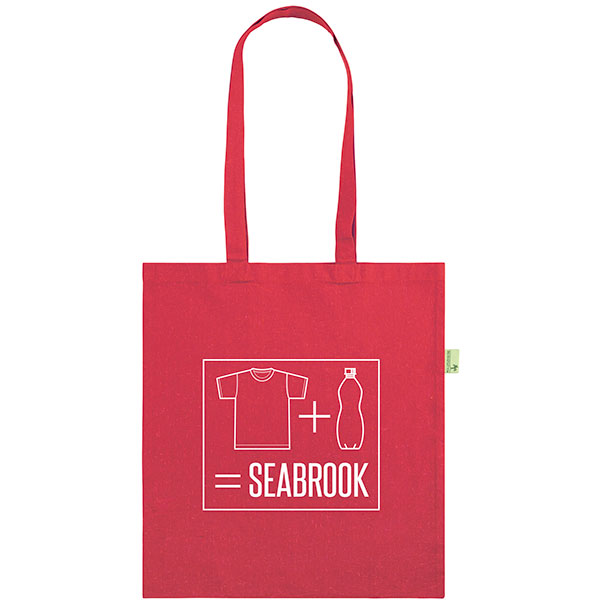

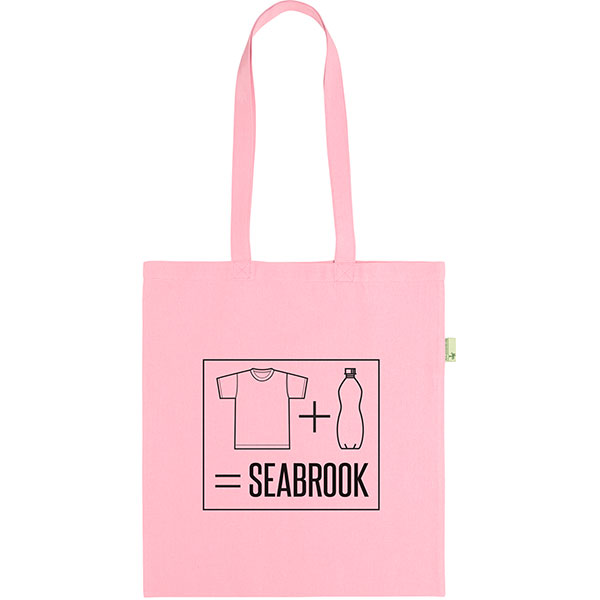

- A4 fits without creasing: We love the Green & Innocent 5oz Fairtrade Cotton Shopper – 1 Colour as a reference point because 420 x 380mm is the size that takes A4 packs without forcing corners and making the bag look overstuffed. Long handles mean you can carry it comfortably when you’re also holding coffee, a phone, or a lanyard.

- Popper keeps shape: We chose the Chevening 12oz Recycled Tote Bag – 1 Colour because it’s a tote that doesn’t slump open in transit. The 12oz recycled blend, bottom gusset, and brass popper keep the load more controlled. If you’re commuting with it daily, that closure stops contents spilling when the bag tips in a car or on a train seat.

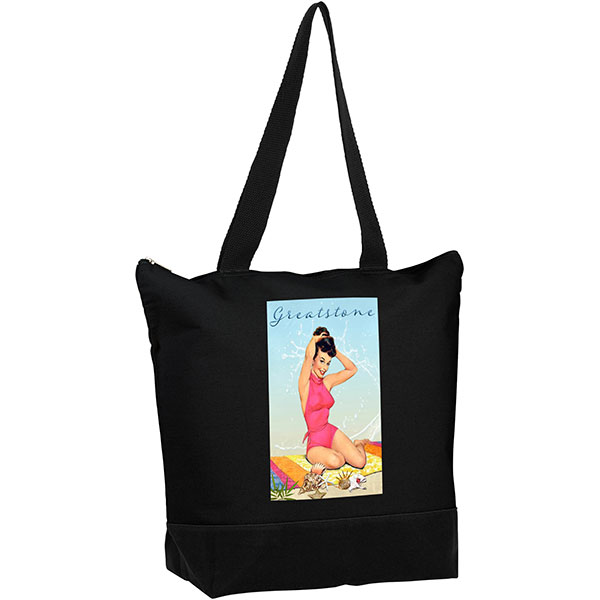

- Protected laptop carry: We recommend the Aqua 14″ GRS Recycled Water Resistant Laptop Tote Bag – 1 Colour because we didn’t want laptops sliding around inside a single-compartment tote. The dedicated 14″ sleeve, organiser pockets, and luggage strap keep tech upright and separated from chargers and bottles. Plus, the water-resistant outer reduces the risk of a light shower soaking what you’re carrying.

- Rigid paper handover: We include the Size 3 Laminated Paper Carrier Bag because we wanted a paper option that doesn’t crease and tear as soon as it gets some weight. The UK-made laminated build and rope handles hold shape through pop-ups and retail handovers. CMYK/digital print on both sides and gussets lets you run bigger branding without it rubbing off like basic paper carriers.

Role: Technical Content Formatter & HTML Architect.